Non-Destructive Testing

NON-DESTRUCTIVE TESTING (NDT) IN ARIZONA

Non-destructive testing (NDT) is a wide group of analysis techniques used in science and industry to evaluate the properties of a material, component, or system without causing damage. Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research.

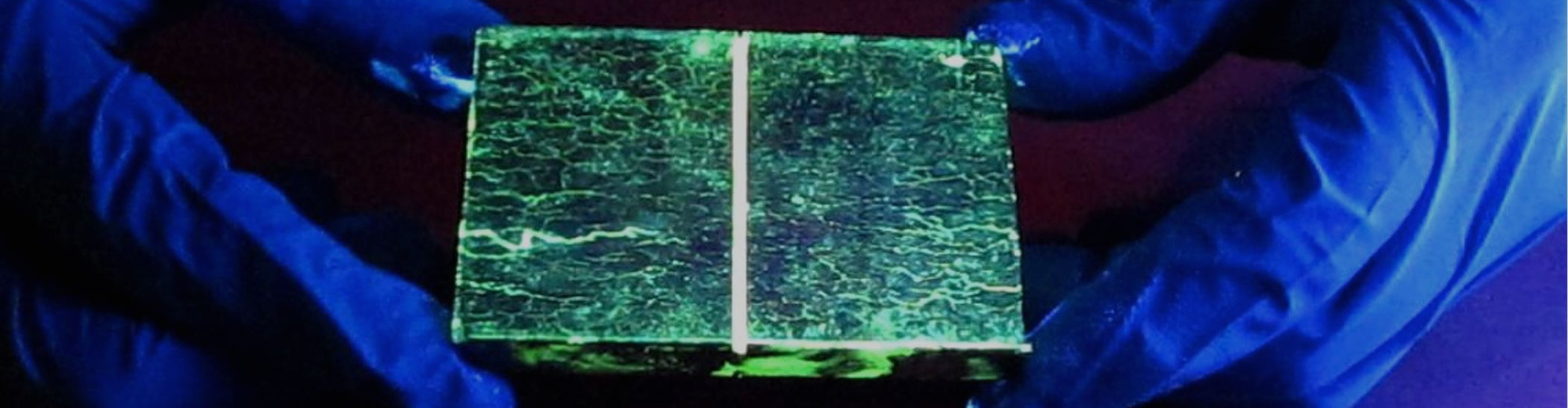

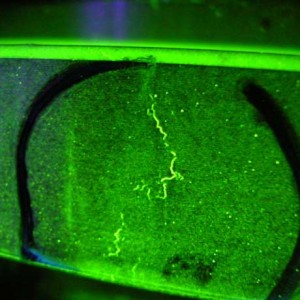

One method (liquid penetrant testing) involves using dyes, fluorescent or non-fluorescent, in fluids for non-magnetic materials, usually metals. Another commonly used NDT method used on ferrous materials involves the application of fine iron particles (either liquid or dry dust) that are applied to a part while it is in an externally magnetized state (magnetic-particle testing). The particles will be attracted to leakage fields within the test object and form on the object’s surface. Magnetic particle testing can reveal surface & some sub-surface defects within the part.

Non-Destructive Testing Properties

To support our one-source solution business model, CRC Surface Technologies provides two NDT inspection services: Magnetic Particle and Liquid Penetrant testing. Both are conducted onsite by our certified NDT Inspectors and audited regularly by Nadcap.

To learn more about our Non-Destructive (NDT) services, contact sales at (602) 288‐6190 or visit our operation located at