Electroless Nickel Plating

Electroless Nickel Plating Services Phoenix, AZ

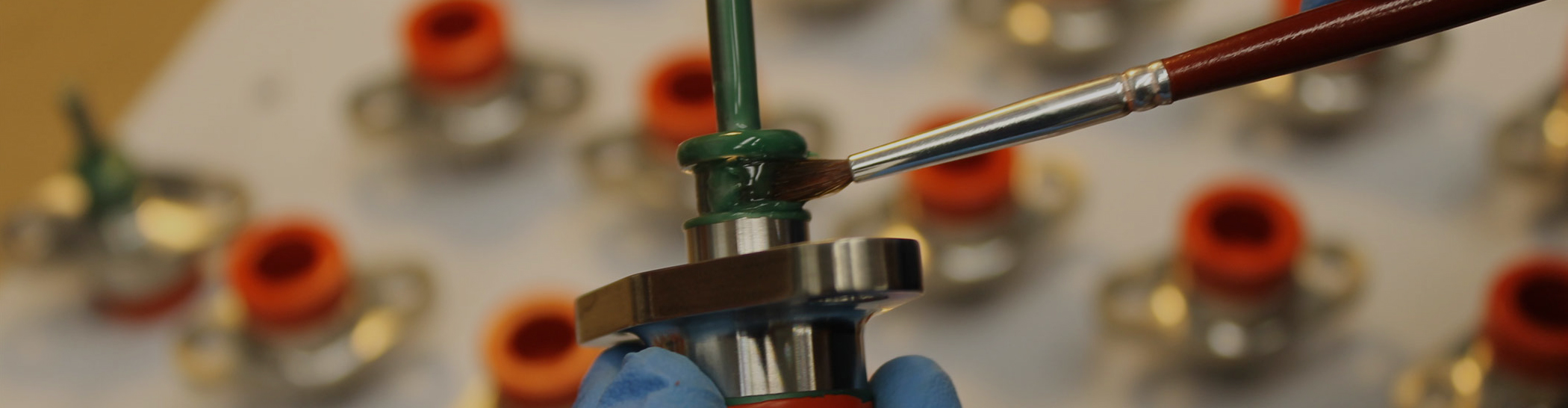

Electroless nickel plating is an auto-catalytic reaction used to deposit a coating of nickel on a substrate. Unlike electroplating, it is not necessary to pass an electric current through the solution to form a deposit. This plating technique is to prevent corrosion and wear. Electroless nickel techniques can also be used to manufacture composite coatings by suspending powder in the bath. Electroless nickel plating has several advantages versus electroplating.

Electroless Nickel Plating Properties

- Free from flux-density and power supply issues, it provides an even deposit regardless of workpiece geometry, and with the proper pre-plate catalyst, can deposit on non-conductive surfaces.

- Exceptionally good for part salvage purposes.

- Good corrosion, oxidation, and wear resistance.

- Facilitates soldering on aluminum and brazing on stainless steel.

- Class 1 and Class 2 coated steel parts, Rockwell C40 or above, are baked for hydrogen embrittlement relief. Class 2 coated parts are additionally heated to 500 degrees F or more to harden the nickel deposit to 800 Knoop or better. Class 3 and 4 coated parts shall be baked for 1 to 1.5 hours at 375 degrees F or 250 degrees F.

Due to the high hardness of the coating, it can be used to salvage worn parts. Coatings of 25 to 100 micrometers can be applied and machined back to final dimensions. Its uniform deposition profile means it can be applied to complex components not readily suited to other hard-wearing coatings like hard chromium. CRC Surface Technologies offers mid (5 to 9%) and high (10 to 13%) phosphorus electroless nickel plating processes. Applicable specifications for electroless nickel are MIL-C-26074, MIL-F-14072 (M265), MIL-STD-171, ASTM B733, AMS 2404 and ASTM B656.

To learn more about our electroless nickel plating services, contact sales at (602) 288‐6190 or visit our operation located at