02 Nov What Is Porosity in Electroplating?

Electroplating is a widely used process for applying a thin layer of metal onto a substrate. Depending on the metal used, this process can enhance many properties of the substrate, such as corrosion resistance, aesthetics, durability, and more.

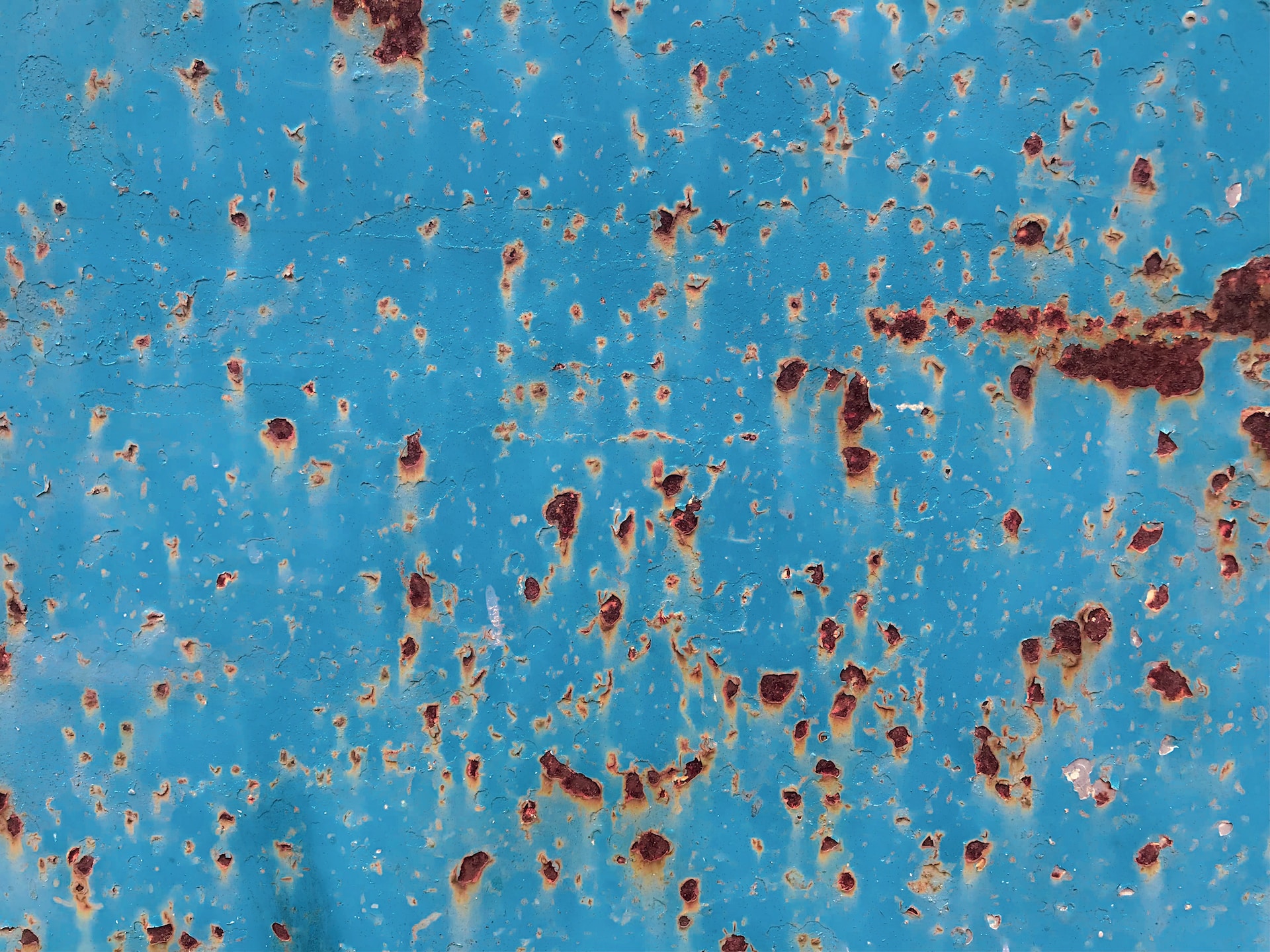

However, electroplating is a delicate process that requires careful preparation and monitoring. Even the smallest mistakes can lead to defects like porosity (tiny holes or voids within the plated metal layer). Porosity can take various forms, such as pinholes, micropores, or even large gaps. These tiny holes or “pores” can be detrimental to the performance, appearance, and overall integrity of the plated component.

Why Is Porosity a Problem?

Porosity can compromise the quality of electroplated items in several different ways. For instance, porous plating allows corrosion to penetrate the substrate and reduce its overall corrosion resistance. It can also cause poor adhesion between the plating layer and the substrate, which leads to flaking or peeling. Porosity can even negatively affect the appearance of a plated product.

What Causes Porosity in Plated Metal?

1. Gas Bubbles

During the electroplating process, bubbles of hydrogen, oxygen, or other gasses can form on the substrate’s surface. If they are not managed properly, these gas bubbles can become trapped in the plating layer, creating tiny holes.

2. Inadequate Cleaning

Properly cleaning the substrate before it goes into the electroplating bath is crucial. Any residues, contaminants, oils, or debris left behind on the surface of the metal can cause gas bubbles, flaws, and other defects.

3. Insufficient Coating Thickness

To ensure a durable, uniform coating, it’s essential to understand the required thicknesses for different plating metals. If a coating is too thin, it can become porous or it might even fail to cover the entire surface.

How to Prevent Porosity in Electroplating

Step 1: Surface Preparation

Thoroughly cleaning and properly preparing the substrate is the foundation of successful electroplating. To prevent porosity, it’s important to make sure that the surface is uniform and free of contaminants. Grinding and polishing can help remove irregularities and provide a smooth base for electroplating. Deoxidizing the substrate may also be necessary if the metal has already developed an oxide layer. And degreasing the surface is crucial in eliminating contaminants and oils that may lead to porosity.

Step 2: Optimized Plating Conditions

A consistent and well-balanced chemical bath composition must be maintained to prevent gas bubbles. The temperature of the bath must also be monitored to ensure that it stays at the correct temperature for the specific plating process. The electrical current density applied to the bath will also need to be controlled to achieve high quality results.

Step 3: Quality Control

Thorough quality control measures are integral to any electroplating process. Non-destructive testing methods like liquid penetrant testing can detect porosity and other hidden defects in electroplating. And professional inspections performed at different stages of the electroplating process will catch any obvious surface defects, like pin holes or voids.

Professional Electroplating Services in Phoenix, Arizona

Only a professional metal finishing provider can guarantee that your plated product is free from porosity and other defects. At CRC Surface Technologies, we are experts in preparing, electroplating, and testing a wide variety of substrates. We provide silver, chrome, copper, and many other electroplating services to manufacturers large and small.

Email us at rfq@chemresearchco.com to request a quote, or give us a call at 602-253-4175 to learn more.

Images used under creative commons license – commercial use (11/2/2023). Photo by Jan Antonin Kolar on Unsplash