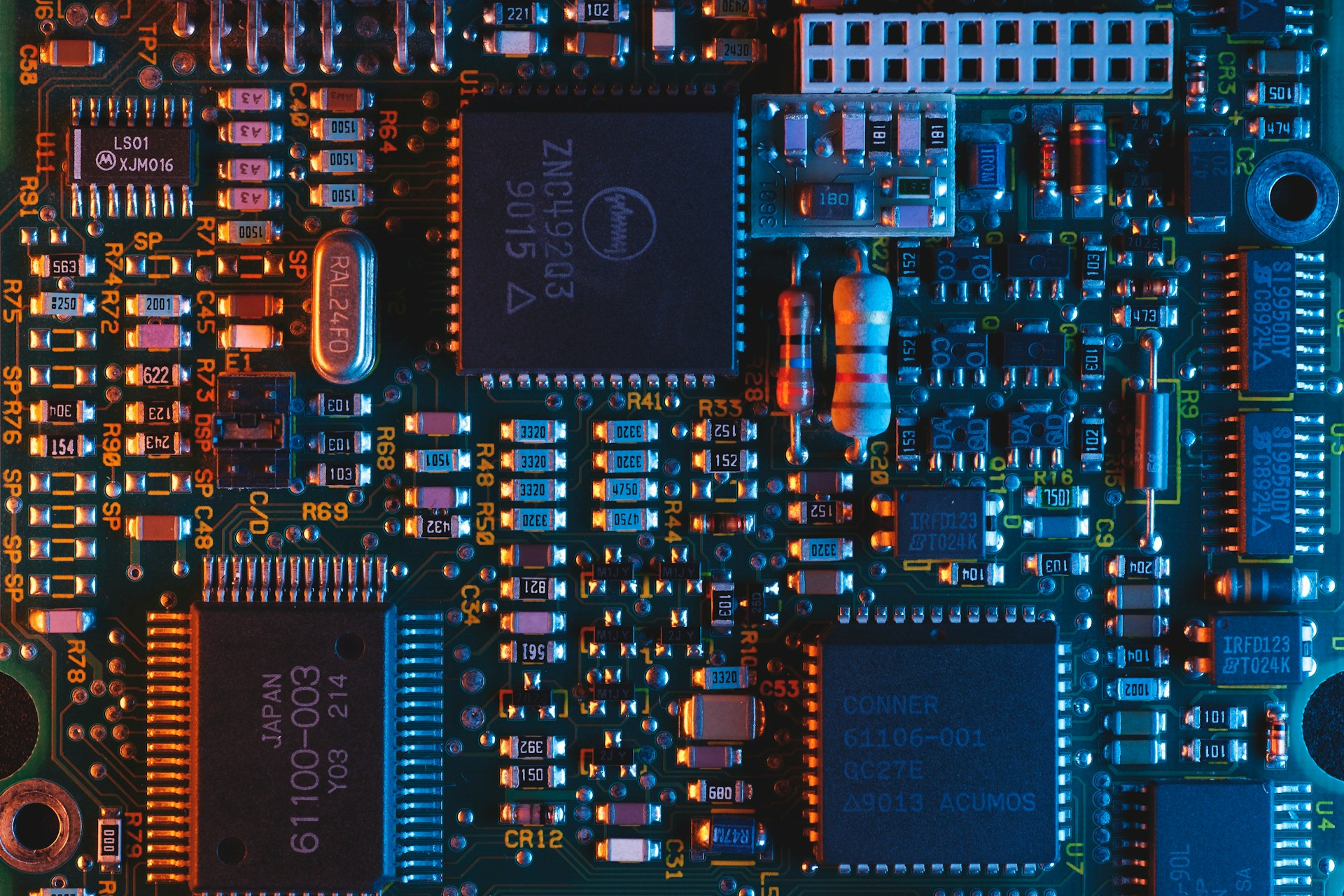

29 Sep Why Metal Finishing Is Essential for High-Tech Electronics

High-tech electronics power everything from smartphones and medical devices to aerospace control systems and electric vehicles. But in order for these devices to perform reliably, efficiently, and safely, their components need to meet the highest standards. Here’s how metal finishing can transform raw components into high-performance parts that meet the demanding requirements of modern technology.

Metal Finishing for Electronics

Metal finishing is a very important part of enhancing electronic parts to improve their performance, reliability, and conductivity.

In the electronics industry, metal finishing often includes treatments like:

- Electroplating deposits a thin layer of silver, nickel, or copper to enhance conductivity and improve corrosion resistance.

- Electroless Nickel Plating provides uniform coverage on complex geometries, improving wear resistance and electrical performance.

- Passivation protects stainless steel components from corrosion while maintaining conductivity.

- Anodizing adds insulation or durability, depending on the application.

These processes ensure that even the smallest electronic components perform optimally in harsh environments and over long lifespans.

Metal finishing is often used on the electronic components in:

- Medical devices (Pacemakers, surgical equipment, and diagnostic machines)

- Aerospace and defense (Radar systems and satellites)

- Consumer electronics (Smartphones, laptops, and wearables)

- Automotive and EVs (Battery connectors, sensors, and control modules)

Why Metal Finishing Matters for High-Tech Electronics

1. Improved Electrical Conductivity

Electronic devices rely on the precise and efficient transmission of electrical signals in order to function properly. Silver, copper, and other conductive finishes help ensure low-resistance connections, which is critical for components like microchips, circuit boards, and connectors.

2. Corrosion and Oxidation Protection

Electronic devices are often exposed to moisture, chemicals, or extreme temperatures—especially in medical and military settings. Metal finishes like nickel plating help protect against corrosion, improving long-term performance and reliability.

3. Enhanced Durability and Wear Resistance

Some high-tech devices have moving parts and connectors that must endure repeated stress from friction. Finishes like electroless nickel plating provide wear resistance, which extends the life of components in demanding applications such as aerospace and automotives.

4. Miniaturization and Precision

As electronics become smaller, precision becomes even more essential. Metal finishing allows for ultra-thin, uniform coatings on tiny, intricate components without compromising performance.

5. Heat and Signal Management

Some finishes can enhance thermal conductivity, helping to dissipate heat, while others provide electrical insulation to prevent short circuits. Both of these characteristics are essential for high-performance electronic systems.

Metal Finishing Services for the Electronics Industry

Working with an experienced metal finishing provider means that your components will exceed the industry standards for performance and reliability. At CRC Surface Technologies in Phoenix, we offer over 33 different metal finishing solutions to local machine shops and manufacturers nationwide.

If you’re looking for a trusted partner to handle your metal finishing needs, please send an email to rfq@chemresearchco.com or call us at 602-253-4175 to request a quote.

Images used under creative commons license – commercial use (9/29/2025). Photo by Umberto on Unsplash