05 Apr Advantages of the Copper Electroplating Process

Copper electroplating is a common and cost-effective process in the metal finishing industry. Because of its unique characteristics and comparatively low costs, copper is regularly used to plate various substrates on its own or used as a base layer for other plated metals. As a leading metal finishing contractor in the Southwest, CRC is happy to explain how copper electroplating offers numerous benefits for industrial manufacturers.

What Can Copper Electroplating Do?

There are several key characteristics that copper always provides, regardless of the plating process used. You may need copper for its conductivity, malleability, or corrosion resistance, depending on your particular industry. Here’s a list of some of the properties of copper and their industrial applications.

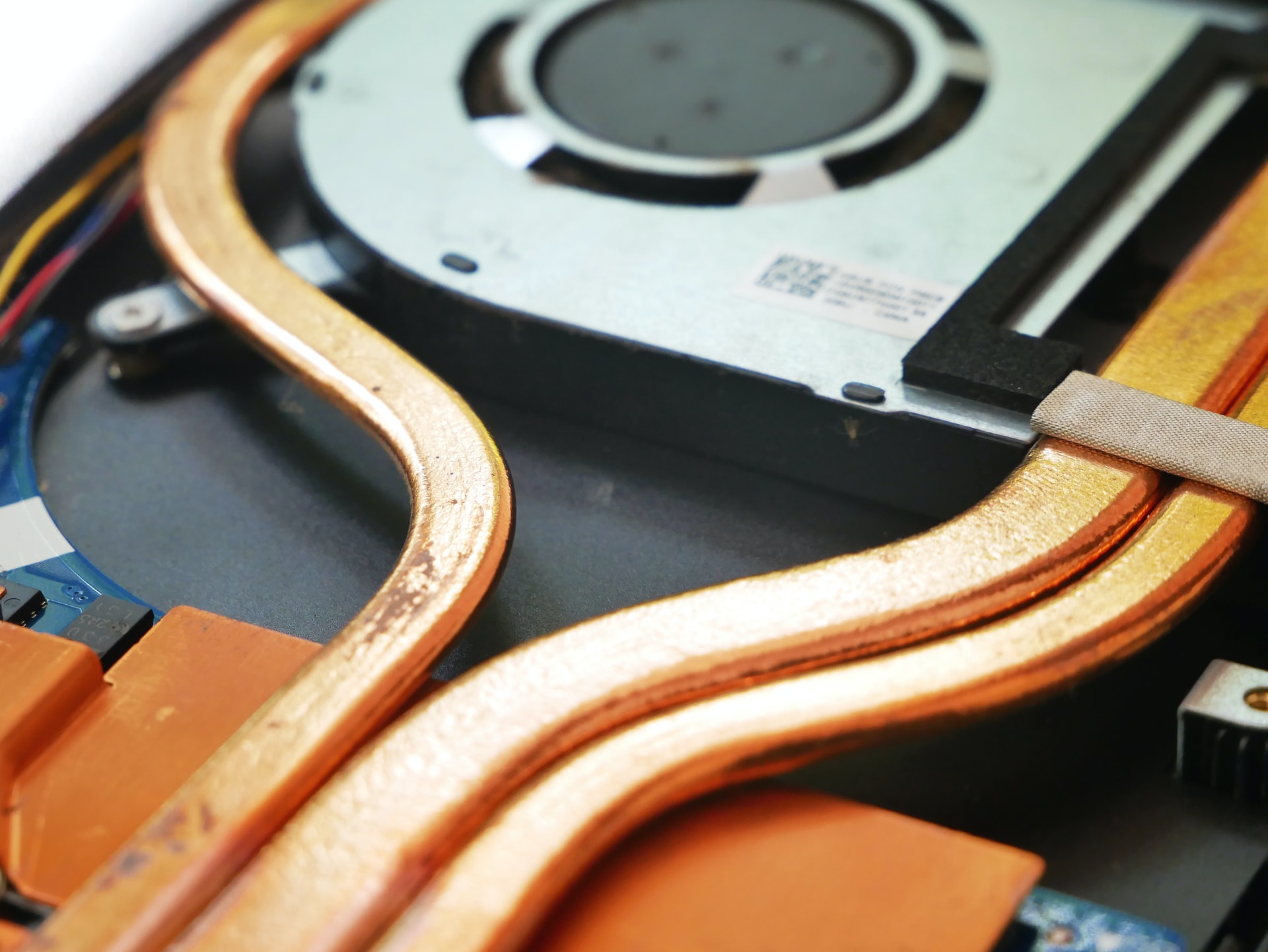

1: Excellent Conductivity

Copper’s electrical conductivity is extremely high, second only to silver. Its lower cost compared to silver makes it a cost-effective solution that will improve a product’s conductivity. This is why manufacturers commonly coat printed circuit boards with copper and use it as a topcoat for steel wires in electrical cables.

2: Malleability

Copper is generally a very soft and malleable metal. This flexibility ensures that it maintains adhesion even if manufacturers bend or manipulate it post-plating. As such, it can be useful when pieces must be shaped or positioned into the machinery that uses them.

3: Excellent Thermal and Corrosion Resistance

Copper provides corrosion resistance to underlying substrates in marine environments. While it is not as effective as nickel plating, copper plating can serve as a base layer for nickel plating. It is also quite effective as a thermal conductor, making it particularly useful in high-temperature environments.

4: Antibacterial Properties

For medical manufacturers, copper electroplating can be an effective and safe solution for sterile components. Copper has antibacterial and antimicrobial properties suitable for equipment used in hospital settings where the risk of disease transmission is a factor. Medical devices commonly use it to transmit signals to diagnostic tools and in small implants that doctors will place inside a patient’s body.

5: Friction Reduction

Copper plating can also act as lubrication for products that need friction reduction. This is especially useful for military manufacturers who produce small arms and artillery munitions that need to be treated with some form of lubrication. Copper electroplating ensures that fired ammunition will cleanly leave its casing, preventing misfires and reducing lead residue. It helps preserve the safety of those using firearms, and saves them time cleaning the weapons as well.

Seeking a Copper Electroplating Expert?

If any of the benefits of copper electroplating could help you as a manufacturer, it’s important that you partner with a contractor who understands your needs. As a leading metal finishing contractor in the Southwest, CRC works to stay at the forefront of safe, effective finishing processes for our clients. Whether you’re a regional or national partner, we’re proud to offer our electroplating services. Contact us today at 602-253-4175 or 877-457-5283 so we can start a relationship that empowers your manufacturing process.

Photo by Vishnu Mohanan on Unsplash.