03 May Non-Destructive Testing Processes and Procedures

Non-destructive testing (NDT) is an expansive selection of tests that manufacturers use to evaluate the properties of materials, components, or systems for scientific and industrial processes. Because NDTs do not cause any damage to the parts being tested, they allow manufacturers to use high-quality, pre-tested components.

Here at CRC we are proud to provide safe, non-destructive testing to our partners as a one-source solution for their metal finishing needs. We also offer onsite magnetic particle testing and liquid penetrant testing at our Arizona facility.

What Is Non-Destructive Testing?

This systematic testing process evaluates the properties of metal components without damaging them. Unlike other tests that deliberately threaten the integrity of the tested materials, NDT provides a cost-effective means to check their quality after production or during usage.

Non-destructive testing helps to identify any deformities or discontinuities that would threaten the overall integrity and reliability of the pieces. It also preserves the safety of the people using the tested materials.

Is Non-Destructive Testing Safe?

Although NDT ensures the safety of tested materials for their end users, some of the tests themselves can be dangerous. Processes such as radiographic and neutron radiographic testing involve aspects that are hazardous to human health. Unless you can implement proper safety protocols and standards for your inspectors, It’s best to rely on a third party for non-destructive testing.

As a metal finishing contractor, CRC offers magnetic particle testing and liquid penetrant testing to our clients. We always ensure that the quality of our work meets our high standards and those of the manufacturing community and its regulators. All of our onsite tests are conducted by certified NDT inspectors and are audited regularly by the National Aerospace and Defense Contractors Accreditation Program (NADCAP).

Liquid Penetrant Testing

Liquid penetrant testing uses low viscosity liquids to reveal fissures in the surfaces of non-porous materials like copper plating. This process is more effective and more accurate than visual inspections alone.

In most cases, non-destructive testing of this type follows a set six-stage process:

- Surface cleaning to remove blocks to the penetrant

- Penetrant application through dipping, spraying, or brushing

- Removal of excess penetrant using water or a solvent

- Application of developer

- Inspection of test surface visually and with cameras

- Post-inspection cleaning

Magnetic Particle Testing

Magnetic particle testing uses magnetic fields to reveal surface discontinuities in ferromagnetic materials. For instance, nickel plating might be examined using magnetic particle testing to ensure its integrity.

Test teams apply very-fine colored ferromagnetic particles to the surface of the tested component. When the magnetic field encounters a discontinuity, the particles visibly indicate any disruptions and defects. Because a discontinuity must be perpendicular to the magnetic field in order to be detected, the test must be applied once in each direction.

The general procedure for magnetic particle testing also follows six steps:

- Surface preparation to remove interference

- Induction of a magnetic field

- Application of magnetic particles to the testing surface

- Examination of the component surface for defects

- Repetition of the test by changing the direction of the magnetic field

- Post-test demagnetization and cleaning

Do You Need Non-Destructive Testing Services?

CRC adheres to the highest non-destructive testing standards for our partners. As Arizona’s finest metal finishing contractor, we aim for nothing less than the best with every project we take on. Contact us today at 602-253-4175 or 877-457-5283 to discuss how our NDT services can enhance your manufacturing process.

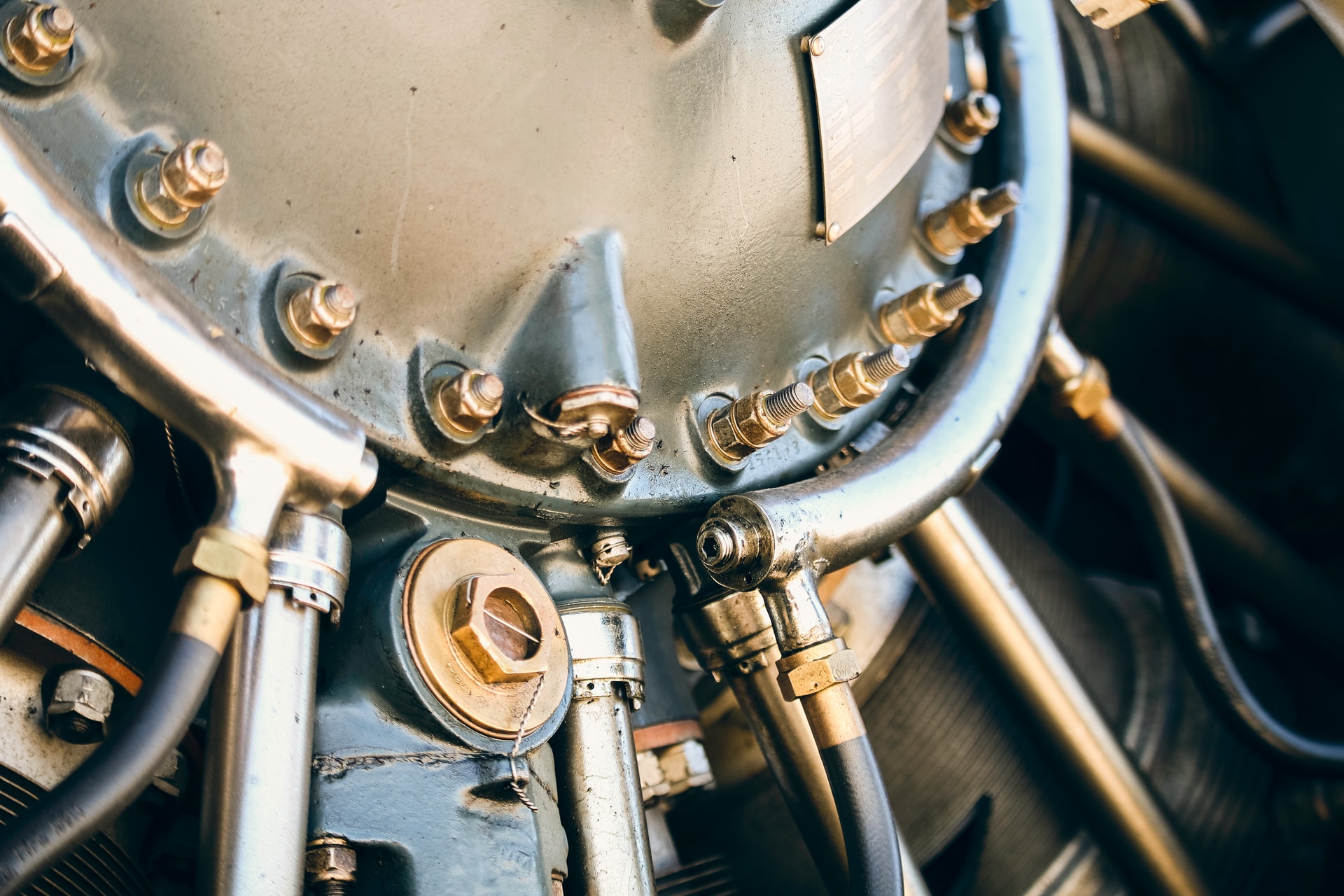

Photo by Aaron Barnaby on Unsplash.