23 May When to Choose Anodized vs. Painted Aluminum

When it comes to finishing aluminum surfaces, anodizing and painting are two of the most popular choices. Both methods have unique advantages, and it can be challenging to choose one over the other. But making the right choice can make a huge difference. We compared anodized aluminum vs. painted aluminum to help you choose the right finish for your application.

Anodized Aluminum

Aluminum anodizing is an electrochemical process that vastly improves the natural oxide layer that forms on aluminum. During the process, the aluminum substrate is submerged in an electrolytic bath. When an electric current is applied, it causes an even layer of aluminum oxide to form on the surface.

The thickness of the anodic layer depends on the type of anodizing process used. Type I anodizing is thinnest and softest, Type II is moderately thick, while Type III is the thickest and hardest. But no matter the type of anodizing, the resulting anodic layer is very durable, and protects the aluminum substrate from corrosion and wear.

Four Advantages of Aluminum Anodizing

- Cost-Effective—Anodized aluminum is cheaper than painted aluminum in the long run, because less maintenance is required.

- Corrosion Resistant—Anodized aluminum is perfect for outdoor applications because it resists rust and other types of corrosion.

- Low Maintenance—Unlike paint, anodizing doesn’t chip or peel, and it does not need to be cleaned as often as painted surfaces.

- Fade Resistant—The anodic layer is unaffected by sunlight and does not fade.

Painted Aluminum

Paint is an organic coating that is simply rolled or sprayed on. Although not as durable as anodizing, painting aluminum can still provide the surface with both a decorative and protective finish. Paint can be chosen in any color, and forms a protective layer on the aluminum surface that seals out moisture and other corrosive substances.

Advantages of Painted Aluminum

- UV Protection—Paint reflects sunlight, protecting the surface of the aluminum from damaging UV rays. However, paint is subject to fading over time.

- Temperature Regulation—Because paint reflects sunlight, it also helps prevent aluminum from overheating.

- Unlimited Color Palette—Paint is available in an unlimited range of colors, while anodizing has limited color choices.

- Color Consistency—It is much easier to maintain color consistency with paint than anodizing.

When Should You Choose Anodized vs. Painted Aluminum?

Whether you should anodize or paint an aluminum surface depends on several factors. For instance, if the substrate will be in contact with food or pharmaceuticals, then anodizing is the better choice because it will not chip or flake and cause contamination.

Anodizing is more durable than paint, so it’s a good choice for substrates that will be subject to harsh environments. It also lasts much longer without needing touch-ups. However, if appearance is the priority, then paint is a better choice because it gives you more creative freedom and color options.

But even if you choose to paint an aluminum substrate, anodizing can be used as a pretreatment. Anodizing the aluminum as a pretreatment offers better corrosion protection than painting alone, and it even helps the paint adhere better.

Aluminum Anodizing in Phoenix, Arizona

At CRC Surface Technologies, we’re experts at anodizing aluminum. We offer all three types of anodizing for a wide range of industries, including aerospace, automotive, defense, and medical applications. We’ll ensure that you get a professional, perfect finish on all your aluminum parts.

Call us at 602-253-4175 to learn more about our services, or if you’d like to receive a quote, email rfq@chemresearchco.com for additional assistance.

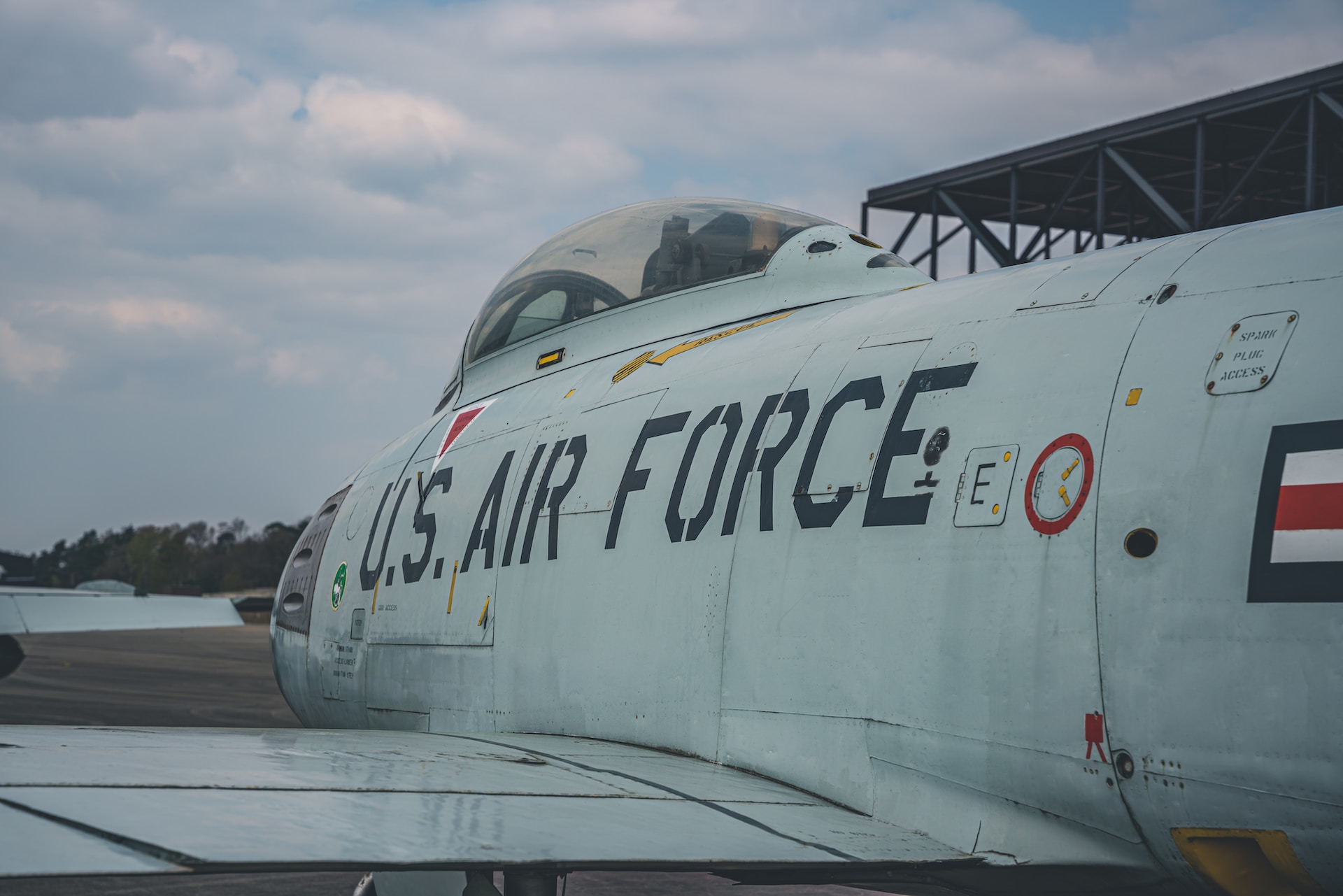

Images used under creative commons license – commercial use (5/23/2023). Photo by Bro Takes Photos on Unsplash