01 Dec What Is Copper Electroplating?

Copper is a popular electroplating metal because of its versatility. It can be used in a wide range of industries, and offers many impressive advantages. Continue reading to learn how copper electroplating works and how it can improve metal parts.

What Is Copper Electroplating, and How Does It Work?

Copper electroplating is the electrochemical process of depositing a layer of copper onto a metal substrate. The electroplating process works by submerging a piece of copper and a metal part into an electrolytic bath, and then applying an electrical current.

The copper serves as an anode, allowing the electrical current to flow through it and release copper ions. The metal substrate is the cathode, which allows it to receive the copper particles. As a result, a protective layer of copper forms on the surface of the metal substrate.

Are There Different Types of Copper Plating?

There are several ways to apply copper plating. At CRC Surface Technologies, we specialize in barrel and rack copper plating.

Barrel Plating

Barrel electroplating is a simple and cost-effective process. During barrel electroplating, the copper and metal parts are placed into a barrel-shaped cage, which slowly rotates while submerged in the electrolytic solution as the electrical current is applied. This type of copper electroplating produces even coverage for high volumes of small parts.

Rack Plating

The rack plating method involves mounting individual metal parts on a rack, and then submerging it into an electrolytic plating solution with the copper. The plating rack securely holds the parts in place as electrical current flows through it and into the metal parts.

Rack plating is ideal for copper plating large or complex parts that can be otherwise difficult to cover evenly. This method also helps prevent scratches and other damage during the plating process that might be caused by sharp edges on the metal substrates. However, because it is a more complex process, rack plating is more expensive than barrel plating.

What Are the Benefits of Copper Electroplating?

No matter the plating process used, there are many advantages to copper electroplating. Copper plating improves many characteristics of metal substrates, including:

- Electrical conductivity

- Malleability

- Thermal resistance

- Corrosion resistance

- Antibacterial and antimicrobial properties

- Lubricity

Copper Plating Uses

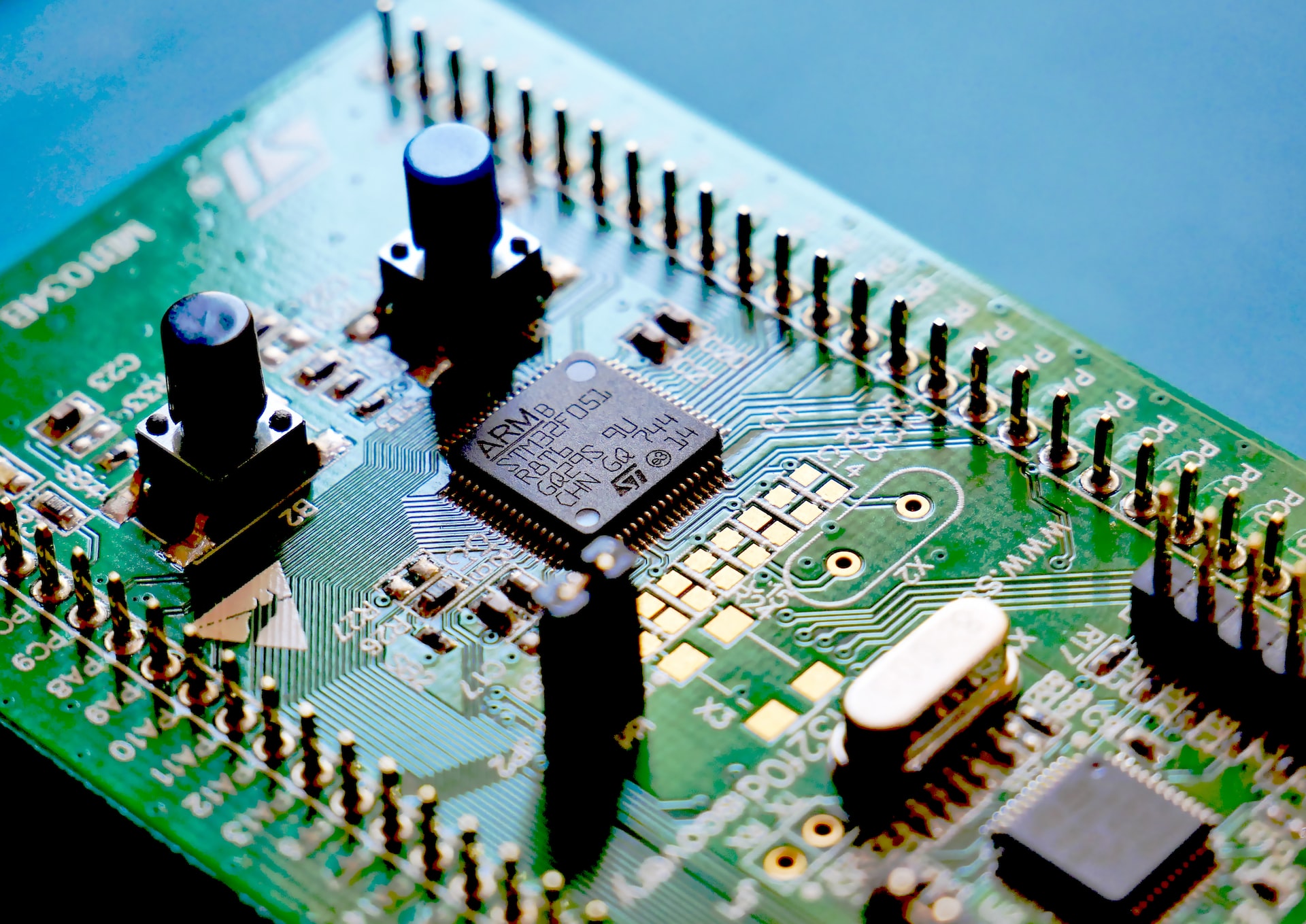

Many different industries use copper plating for a wide range of applications. For example, its antibacterial and antimicrobial properties make it the perfect choice for plating medical and laboratory equipment. And because copper is highly conductive, it’s also a top choice for printed circuit boards in the electronics industry.

Copper is often used in the automotive industry to remove surface imperfections and improve the appearance of aluminum wheels. Copper can even be used as a base layer for nickel plating or silver plating to make the final coating even more effective.

But that’s not all—other industries and manufacturers use copper electroplating for ammunition, artillery, HVAC, power distribution, heat treatment, telecommunication, and fasteners.

Copper Electroplating Services in Phoenix, Arizona

If you’re interested in copper electroplating, then make sure to choose a certified provider. CRC Surface Technologies is NADCAP-Certified and ITAR-registered. As the largest special processing facility in Arizona, we’re well-equipped to handle many of your metal finishing needs. We serve local industries as well as manufacturers across the country.

Call us at 602-253-4175 today to learn more about our copper electroplating services, or email rfq@chemresearchco.com to request a quote.

Images used under creative commons license – commercial use (12/1/2022). Photo by Vishnu Mohanan on Unsplash