31 Aug 8 Common Copper Plating Applications

Copper plating is one of the most widely used metal finishing techniques because it has so many beneficial properties. Its applications range across many industries, from electronic parts to medical instruments, aerospace and communications.

Depositing a layer of copper onto a metal substrate can improve its conductivity, corrosion resistance, and other essential properties. Let’s explore the advantages of copper plating across eight different industries.

What Is Copper Plating Used for?

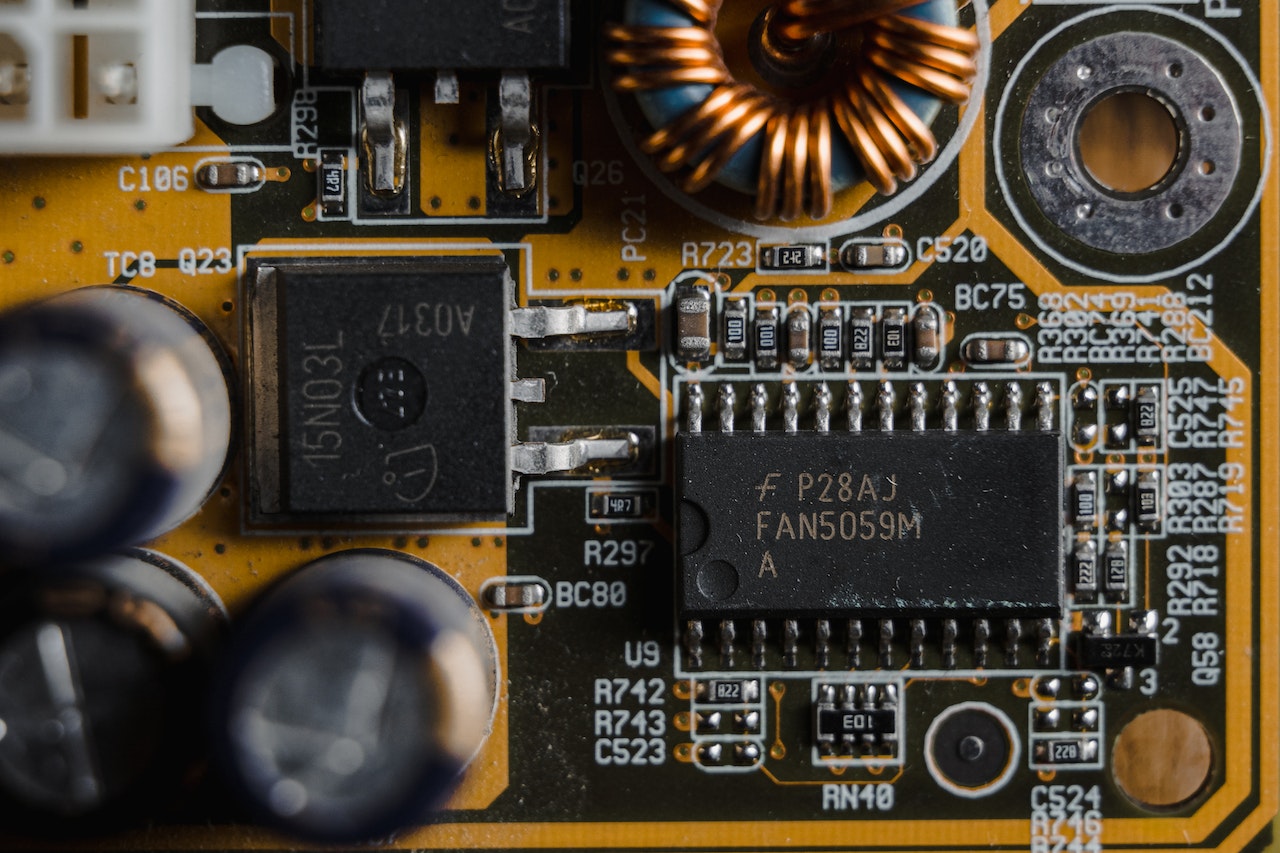

1: Electronics and Electrical Components

Copper’s excellent electrical conductivity makes it a top choice as a plating layer for electrical components. Copper plating helps create conductive pathways that facilitate the flow of electricity. It also protects plated components against corrosion. Printed circuit boards, connectors, semiconductors, electrical wiring, and other parts can all benefit from copper plating.

2: Industrial Machinery

The improved conductivity and corrosion resistance of copper-plated components can enhance the efficiency and longevity of industrial machine parts. Copper-plated gears, shafts, and fasteners play a vital role in minimizing friction and wear, while ensuring that the equipment functions smoothly.

3: Automotive Parts

Copper plating also has numerous applications in the automotive industry. For instance, copper offers increased corrosion resistance, helping protect brake tubing and fittings from corrosion due to road salt. And because copper is also a good heat conductor, many heat exchangers are copper-plated to conduct heat efficiently from the engine.

4: EMI/RFI Shielding

Copper plating also functions as effective shielding for electromagnetic interference (EMI) and radio frequency interference (RFI). The conductive copper surface prevents electromagnetic radiation from interfering with electronic components and devices, preventing electrical malfunctions.

5: Aerospace and Aviation Components

In the aerospace and aviation industries, copper plating is crucial in maintaining the performance and safety of many components. It is often used for EMI/RFI shielding and electrical wiring in aircraft. And its corrosion resistance ensures that critical aerospace parts can survive longer in challenging environments.

6: Telecommunications

Copper plating is essential for the high-speed circuitry and radio frequency transmission needed for telecommunications equipment. It’s often applied to waveguides, inductors, and other radio frequency components in mobile devices as well as wireless infrastructures. Copper-plated connectors, cables, and antennas also provide optimal conductivity for clear and reliable telecommunications.

7: Medical Devices

Copper’s antimicrobial properties make it extremely valuable for manufacturers of medical devices. Copper-plated surfaces inhibit the growth of bacteria and other pathogens, reducing the risk of infections. Instruments, handles, and any other touch surfaces in medical settings are great candidates for copper plating.

8: Marine Uses

Copper plating also has antifouling properties that prevent barnacles, algae, and other organisms from accumulating on the hulls and propellers of ships. Copper-plated marine equipment is easier to clean and minimizes the risk of mechanical breakdowns caused by fouling organisms.

And because copper is highly resistant to salt water, copper plating is often applied to fittings and fasteners on boats and ships to help these components last.

Copper Plating Services in Phoenix, Arizona

If you have metal parts that need a conductive and corrosion-resistant finish, copper is an excellent choice. But creating a quality copper plating takes a high level of expertise. CRC Surface Technologies provides copper plating services for many industries, and we partner with manufacturers both large and small.

Give us a call at 602-253-4175 or send a message to rfq@chemresearchco.com to request a quote.

Images used under creative commons license – commercial use (8/31/2023). Photo by Tima Miroshnichenko on Pexels